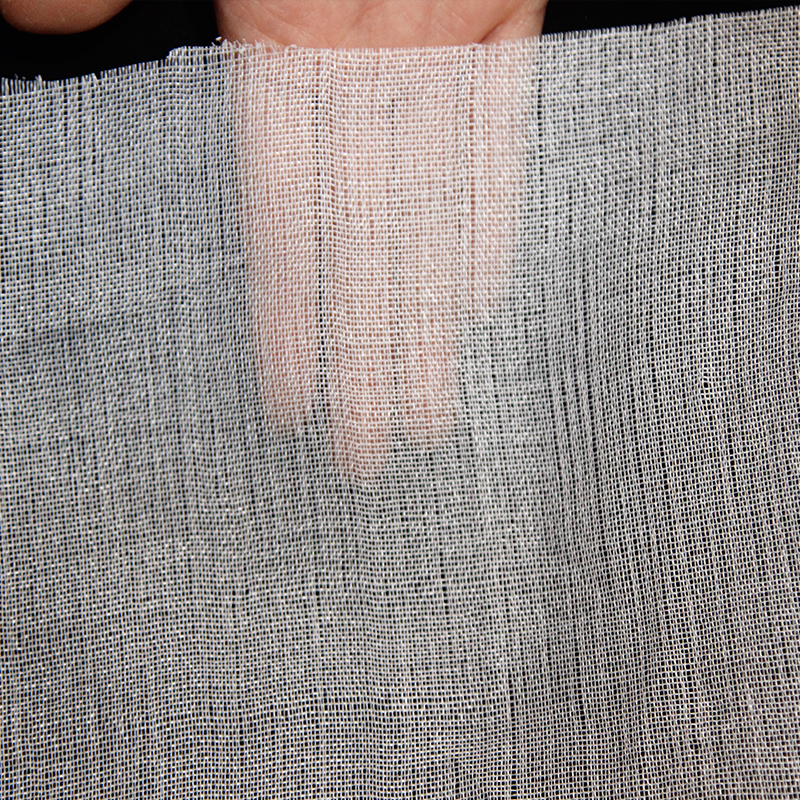

PTFE Scrims with HIgh Compatibility with Different Staple Fibers

Product Introduction

Needle felt is commonly used in industrial filtration applications due to its high filtration efficiency and durability. However, when exposed to high temperatures, the needle felt can lose its structural integrity and become less effective at filtering out particles. This is where the JINYOU PTFE scrim comes in. JINYOU started to promote PTFE scrim in high-temperature needle felt in 2002 when nobody ever thought of such an application at that time.

The use of JINYOU PTFE scrim in high-temperature needle felts proved to be a big success by improving service life and tensile strength. And after 20 years of marketing and experience, nowadays, PTFE scrim has been a conventional and high-performance choice for PPS, Aramid, PI, PTFE felt, etc.

One of the key benefits of using PTFE scrim in high-temperature needle felt is its ability to maintain the fabric's structural integrity at high temperatures. This is important because when the needle felt is exposed to high temperatures, the fibers can melt or fuse, which can reduce the fabric's filtration efficiency. By adding a layer of PTFE scrim to the needle felt, the fabric is better able to withstand high temperatures without losing its shape or structure.

Another benefit of using PTFE scrim in high-temperature needle felt is its chemical resistance. PTFE is highly resistant to a wide range of chemicals, including acids, bases, and solvents. This makes it an ideal material for use in industrial filtration applications where the needle felt may be exposed to harsh chemicals.

In addition to its high temperature and chemical resistance, PTFE scrim also has low friction properties. This can help to reduce wear and tear on the needle felt fabric, which can extend its lifespan and improve its overall performance.

Overall, the use of PTFE scrim in high temperature needle felt is a promising area of research in the field of industrial filtration. By improving the fabric's resistance to high temperatures and chemical exposure, PTFE scrim can help to improve the efficiency and durability of needle felt in a wide range of industrial application. Nowadays, PTFE scrim has been used in Aramid felt, PPS felt, PI felt and PTFE felt etc. to elongate felt service life with better performance.

Overall, the use of PTFE scrim in high-temperature needle felt is a promising area of research in the field of industrial filtration. By improving the fabric's resistance to high temperatures and chemical exposure, PTFE scrim can help to improve the efficiency and durability of needle felt in a wide range of industrial applications. Nowadays, PTFE scrim has been used in Aramid felt, PPS felt, PI felt and PTFE felt, etc. to elongate felt service life with better performance.

JINYOU PTFE Scrim Features

● Woven by mono-filament

● Chemical Resistance from PH0-PH14

● UV Resistance

● Wearing resistance

● Non-aging

JINYOU PTFE Scrim Strength

● Consistent Titre

● Strong strength

● Different variation of density

● Different variation of weight

● Superior strength retention under high temperature

● Special structure without movement during weaving

● Excellent support for Aramid felt, PPS felt, PI felt and PTFE felt with better performance, longer service life and lower cost.

Standard Series

| Model | JUC#103 | JUC#115 | JUC#125 | JUC#135 |

| Titre | 500den | 500den | 500den | 500den |

| warp and weft density | 11*7/cm | 12.8*8/cm | 12.8*10/cm | 13.5*12/cm |

| Weight | 103gsm | 115gsm | 125gsm | 140gsm |

| Operating Temperature |

-190~260°C |

|||

| Warp Strength | >850N/5cm | >970N/5cm | >970N/5cm | >1070N/5cm |

| Weft Strength | >500N/5cm | >620N/5cm | >780N/5cm | >900N/5cm |