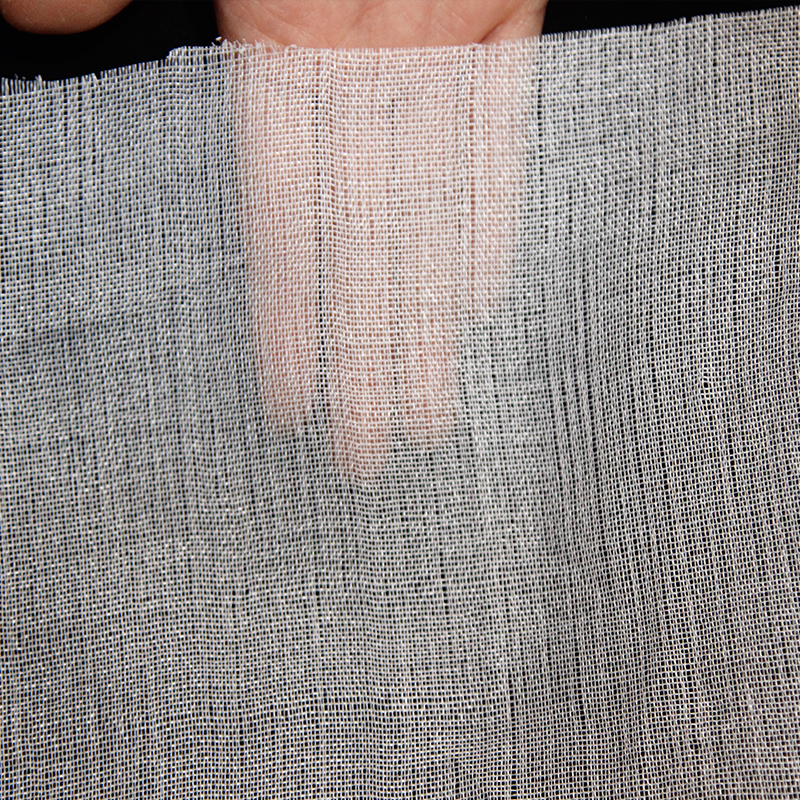

PTFE Yarn with Low Heat-shrinkage for Multipurpose Weaving

Product Introduction

One of the most notable properties of PTFE yarn is its chemical resistance. It is highly resistant to most chemicals, including acids, bases, and solvents. This makes it an ideal material for use in chemical processing industries, waste to energy, powerplant etc.

Another important property of PTFE yarn is its high temperature resistance. It can withstand temperatures up to 260°C without losing its mechanical properties. This makes it an ideal material for use in high-temperature applications, such as in the aerospace industry, where it is used to make seals and gaskets for aircraft engines.

When it comes to outdoor application, the superior UV resistance is another important features of PTFE yarn to reach extraordinary service life.

In a word, PTFE yarn is a synthetic material that has unique properties that make it an ideal material for use in various industries. Its chemical resistance, high temperature resistance and UV resistance make it an ideal material for use in the production of PTFE scrim for high temperature needle felts and woven fabric in air filtration, electronic application or outdoor fabric. It is likely that PTFE yarn will continue to be used in new and innovative ways.

JINYOU makes PTFE yarn with versatile denier varying from 90den up to 4800den.

We also offer different colors of PTFE yarn for different customers’ requests.

JINYOU proprietary PTFE yarn achieves strong strength retention at high temperature.

JINYOU PTFE Yarn Features

● Mono-filament

● Varies from 90den to 4800den

● Chemical Resistance from PH0-PH14

● Superior UV Resistance

● Wearing resistance

● Non-aging

JINYOU Strength

● Consistent Titre

● Strong strength

● Different colors

● Srong strength retention under high temperature

● Denier varies from 90den up to 4800den

● 4 tons of capacity per day

● 25+years production history

● Customer tailored